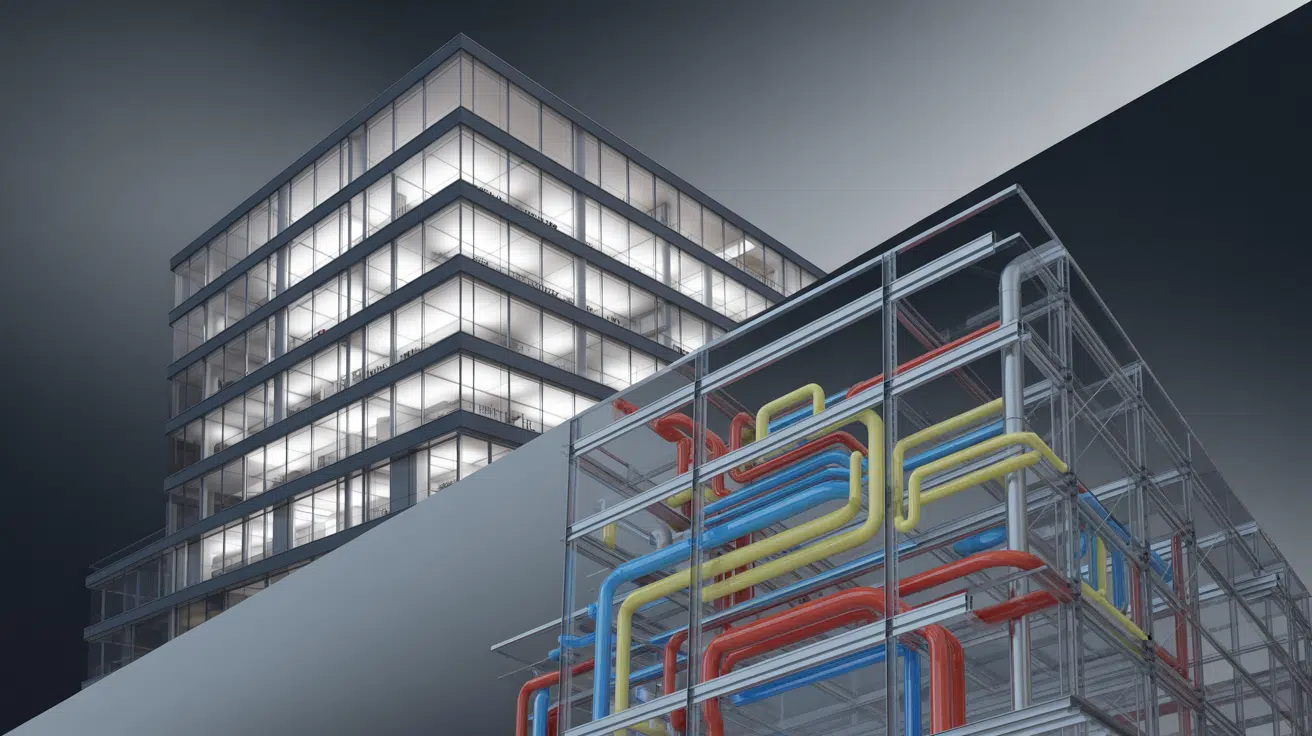

In modern construction, getting things right the first time isn’t just preferred—it’s necessary. This is especially true for MEP systems, which include the mechanical, electrical, and plumbing components of a building. These systems must be carefully planned and coordinated to avoid delays, cost overruns, and conflicts during construction.

This is where BIM for MEP plays a powerful role.

BIM, or Building Information Modeling, brings all the MEP elements into a single digital model. Instead of working in isolation, architects, engineers, and contractors can now collaborate using accurate 3D models that include detailed information about every pipe, wire, duct, and system.

The result? Fewer surprises on site, better coordination among teams, and a smoother construction process overall.

In this blog, we’ll explore how BIM for MEP works, its key benefits, and why it’s becoming essential for delivering high-quality, cost-effective building projects.

What is BIM for MEP and How Does It Work?

If you’re part of a construction or design team, you already know how critical MEP systems—Mechanical, Electrical, and Plumbing are to any building project. But coordinating them smoothly across disciplines? That’s often where things get messy.

This is where BIM for MEP steps in—and changes the game completely.

First, what exactly is BIM for MEP?

BIM for MEP is the process of creating a smart, data-driven 3D digital representation of all MEP systems within a building. That includes:

- Mechanical systems: HVAC, ductwork, heating and cooling components.

- Electrical systems: Wiring, lighting, power distribution, panels, emergency systems.

- Plumbing systems: Pipes, drainage, water supply lines, valves, and fixtures.

But here’s the real difference: unlike traditional CAD or 2D blueprints, BIM models are intelligent and integrated. Every object in the model, whether it’s a pipe or a panel comes with embedded data such as size, material, flow rate, manufacturer specs, and maintenance requirements.

That means you’re not just drawing, you’re planning, predicting, and managing the entire system throughout the project lifecycle.

How does it actually work?

Let’s walk through it step by step.

1. 3D Modeling

Using powerful tools like Autodesk Revit, engineers model every MEP element in 3D. These aren’t just visual placeholders—they behave like real-world objects. You can rotate, inspect, and modify them easily within a shared digital environment.

2. Information-Rich Components

Each system component contains detailed metadata. For example, a duct segment won’t just show its size—it will also include airflow data, material type, and insulation specs. This adds a deeper layer of intelligence to your design.

3. Clash Detection & Coordination

This is a game-changer. BIM software automatically identifies clashes—like a pipe running through a beam or a cable tray overlapping a duct—long before construction begins. You can fix these issues virtually, which helps avoid costly rework and delays.

4. Cross-Disciplinary Collaboration

All stakeholders—architects, structural engineers, MEP consultants, contractors—can work on a common data environment (CDE). Updates made by one discipline are reflected in real time for all, reducing communication gaps and ensuring a unified workflow.

5. Performance Analysis

You can simulate energy efficiency, HVAC airflow, lighting distribution, and water usage early in the design phase. This leads to better design decisions and compliance with building codes and green certifications like LEED or IGBC.

6. Construction-Ready Documentation

Once the model is finalized, BIM generates precise construction documents—such as layouts, schedules, and bills of quantities—directly from the model, eliminating manual errors and reducing turnaround time.

7. Lifecycle Management

BIM doesn’t end at handover. Facility managers can use the model to track maintenance schedules, equipment data, and replacement history. It becomes a living document for building operations.

The Role of BIM in MEP Projects

Think of BIM not just as software—but as a strategic process that transforms how MEP systems are designed, coordinated, and executed. In MEP-intensive projects, where different disciplines overlap in tight spaces, BIM becomes essential—not optional.

But what role does it really play? Let’s unpack it.

1. Centralized Design Coordination

In a traditional workflow, mechanical, electrical, and plumbing engineers often work in silos. This leads to clashes, delays, and last-minute revisions. BIM brings all these systems into a central digital environment, enabling real-time collaboration across teams. Everyone works on the same model, reducing communication errors and siloed updates.

2. Improved Design Accuracy

BIM allows for precise placement of MEP components—based on actual building constraints and architectural layouts. For example, ducts can be routed around beams, plumbing lines placed with correct slopes, and electrical trays coordinated with ceiling heights—all with engineering-grade precision.

3. Clash Detection and Resolution

This is one of BIM’s most powerful features for MEP. It automatically identifies physical conflicts between systems—like a pipe clashing with a beam or a light fixture overlapping a duct. Instead of finding these issues on-site (which can be expensive to fix), teams resolve them during the design stage using clash detection tools like Navisworks.

4. Data-Driven Decision Making

Each element in the BIM model is loaded with data—pressure ratings, material specs, equipment loads, and more. This rich dataset enables engineers and project managers to make informed choices on equipment selection, space planning, and system performance.

5. Seamless Documentation and Scheduling

BIM automates the creation of construction documents such as shop drawings, layout plans, schedules, and material take-offs. Because the documents are generated from the live model, they’re always up to date and highly accurate.

6. Cost and Time Optimization

By identifying potential issues early, coordinating across disciplines, and automating documentation, BIM significantly reduces rework, delays, and budget overruns. It enables a more predictable and efficient delivery of MEP scopes.

7. Support for Sustainability Goals

BIM helps evaluate energy efficiency and system performance at the design stage. Whether it’s simulating HVAC loads, reducing water usage, or selecting low-energy lighting, BIM supports sustainable MEP design and compliance with global green building standards.

How Is BIM Applied in MEP Projects?

Here’s where it gets practical. BIM isn’t just a modeling tool—it’s a structured process that supports MEP teams from concept to commissioning. Whether you’re planning ductwork in a hospital or plumbing in a commercial tower, BIM brings visibility, accuracy, and control.

Here’s how it works in practice:

1. Conceptual Planning and Early Design

At the start, MEP engineers use BIM to lay out conceptual system paths routing major equipment, estimating loads, and identifying space requirements. This helps stakeholders visualize where mechanical rooms, risers, or main lines will go well before construction drawings are created.

2. Detailed 3D Modeling

Once the architectural and structural models are in place, MEP engineers build their systems into the BIM environment. This includes:

- HVAC ducts and diffusers

- Electrical conduits, cable trays, and fixtures

- Plumbing lines, pumps, and valves

Everything is modeled to scale, and in full 3D, enabling full visualization and coordination.

3. Coordination and Clash Detection

With multiple systems occupying the same physical space, coordination is critical. BIM tools like Autodesk Revit and Navisworks help detect conflicts between MEP elements—or between MEP and structural/architectural systems. These issues are resolved digitally before they become costly problems on-site.

4. Scheduling and Phasing (4D BIM)

By linking the 3D MEP model to the construction timeline, teams can plan when each component will be installed. This 4D BIM integration helps avoid worksite congestion, manage labor, and sequence installations correctly—especially important in fast-track or large-scale projects.

5. Quantity Takeoffs and Cost Estimation (5D BIM)

Each model component contains metadata—like material type, size, and quantity. BIM tools extract this data automatically to generate Each model component contains metadata—like material type, size, and quantity. BIM tools extract this data automatically to generate accurate BoQs (Bills of Quantities) and cost estimates, helping control budgets and reduce waste. Utilizing Bim for MEP projects ensures streamlined coordination and precise execution of mechanical, electrical, and plumbing systems, enhancing overall project efficiency and quality assurance. By integrating Bim for MEP, project stakeholders can effectively collaborate, optimize system performance, and achieve cost-effective solutions tailored to specific project requirements. and cost estimates, helping control budgets and reduce waste.

6. Fabrication and Prefabrication

With detailed BIM models, contractors can send MEP system data directly to fabrication shops. This supports off-site prefabrication of duct sections, pipe assemblies, and even electrical modules—leading to faster, safer, and more precise installation.

7. Installation Guidance and Field Use

On site, field teams use BIM viewers on tablets or AR tools to view models in real time. This guides installation with high accuracy—reducing errors, rework, and misinterpretations of 2D drawings.

8. As-Built Modeling and Facility Handover

After completion, the BIM model is updated to reflect the actual installed conditions—known as the as-built model. This becomes a valuable digital asset for the facility team, supporting operations, maintenance, and future renovations.

7 Ways BIM Is Transforming MEP Projects

BIM isn’t just improving MEP workflows—it’s redefining them. From coordination to maintenance, here are seven powerful ways BIM is changing how MEP engineers and contractors work.

1. Seamless Design Coordination Across Disciplines

Gone are the days of siloed workflows. BIM allows real-time collaboration between mechanical, electrical, and plumbing engineers—within the same model. This ensures every system works together without clashes, helping avoid rework and delays later in the project.

2. Clash Detection That Saves Time and Money

Using tools like Navisworks or BIM 360, MEP professionals can automatically detect clashes between ductwork, piping, cable trays, and structural elements. These issues are resolved virtually, long before they hit the construction site—saving time, materials, and change orders.

3. Improved Accuracy in Load Calculations and Equipment Sizing

With BIM, engineers can simulate building performance using real-world data. This means more accurate HVAC sizing, electrical load calculations, and plumbing flow analysis—leading to better system performance and energy efficiency.

4. Faster Prefabrication with Precise Models

Detailed 3D BIM models can be exported directly to fabrication software. This allows for off-site prefabrication of ductwork, piping assemblies, and electrical panels—reducing labor time on-site and improving safety and installation quality.

5. Clear Installation Guidance for Field Teams

Field crews can access BIM models on tablets or AR devices, getting exact coordinates for every component—no more guesswork. This reduces dependency on paper drawings and cuts installation errors significantly.

6. Cost Control and Quantity Takeoffs

Because every element in a BIM model is data-rich, generating Bills of Quantities (BoQ) is fast and accurate. You can track material costs, labor, and system performance in real time—helping stay on budget throughout the project lifecycle.

7. Better Facility Management Post-Construction

Once the project is complete, the BIM model becomes a digital twin of the MEP systems. Facility managers can use it for maintenance scheduling, part replacement, or future upgrades—boosting the building’s long-term operational efficiency.

Conclusion:

If you’re still asking whether BIM is worth it for MEP, the answer is clear: absolutely. The integration of Building Information Modeling into mechanical, electrical, and plumbing systems has moved from being a competitive advantage to becoming an industry standard.

Why? Because BIM doesn’t just enhance design—it transforms the entire project lifecycle. From early-stage coordination and accurate modeling to clash detection, cost control, and facility management, BIM ensures your MEP systems are smarter, more efficient, and better integrated.

At BIM to BIM Studio, we specialize in delivering MEP BIM services that align with global standards and push the boundaries of what’s possible. Whether you’re working on a residential high-rise or a complex infrastructure project, our MEP experts can help you leverage BIM to its full potential—saving time, reducing costs, and improving outcomes

FAQs:

- What is BIM in MEP?

BIM in MEP refers to using Building Information Modeling to design and coordinate mechanical, electrical, and plumbing systems. - Which is better, MEP or BIM?

BIM is a process, while MEP is a discipline—BIM enhances MEP by improving accuracy and collaboration. - What software do MEP engineers use?

MEP engineers commonly use Revit, AutoCAD MEP, Navisworks, and BIM 360 for design and coordination. - Is MEP included in Revit?

Yes, Revit has built-in tools specifically for MEP modeling and design.