7 Ways AI in BIM Is Reshaping Construction

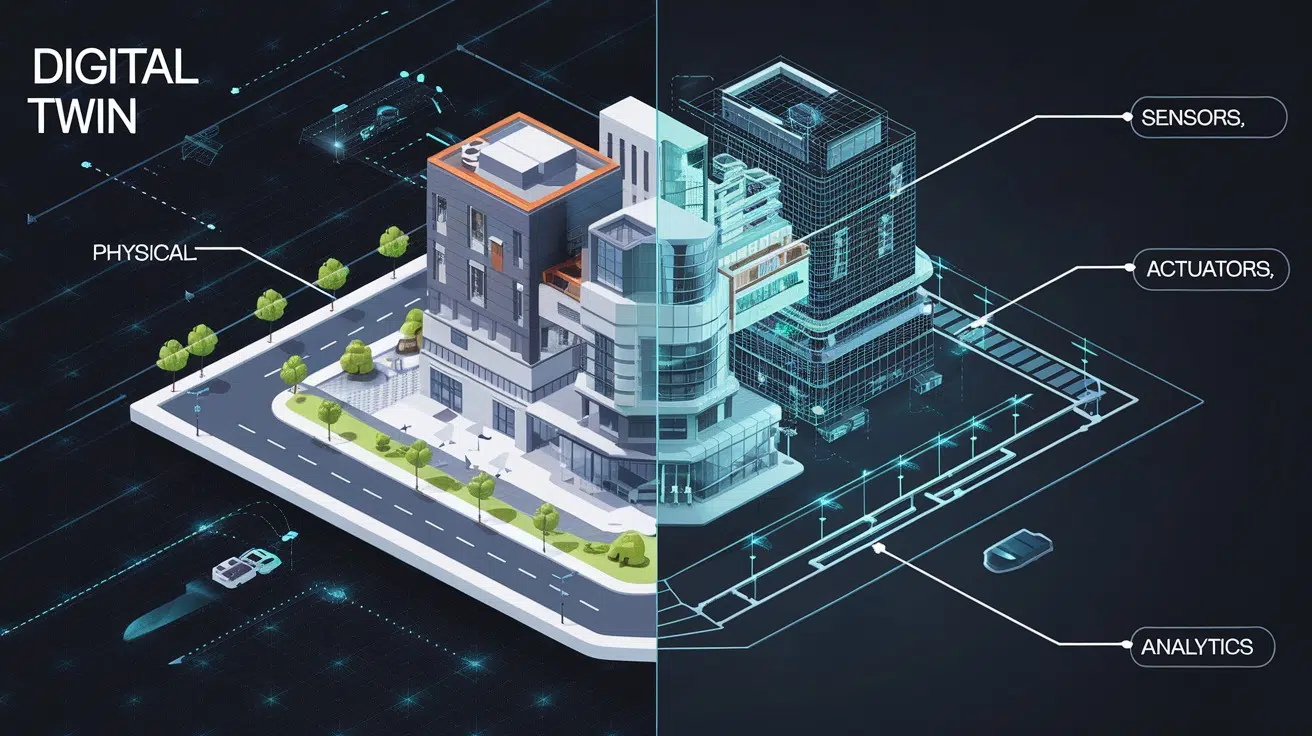

You’ve probably heard the buzz around AI and BIM, but here’s the big question: How is AI in BIM actually reshaping construction? Well, this combination is not just the future; it’s already starting to change the way we build, design, and manage projects. By merging artificial intelligence with building information modeling, the construction industry is stepping into a new era of efficiency and innovation. Now, you might be wondering, “What exactly does this integration mean for me or my projects?” It’s simple. AI brings smart automation, predictive analytics, and real-time data processing into the BIM framework. Imagine being able to predict potential issues before they even arise or adjusting designs instantly based on real-time data—AI is making this a reality. This is far beyond traditional methods; it’s about making every decision smarter and faster. But here’s the exciting part: AI in BIM is just the beginning. In this post, we’re going to explore how AI is transforming the construction industry, from the existing capabilities of BIM to its future potential. So, if you’re ready to dive into how AI can elevate your projects, keep reading. You’re in for a real treat. Existing Capabilities of BIM Before we dive into how AI transforms BIM, let’s first understand what BIM already brings to the table. These core features are what make it such a powerful foundation for smart construction: 3D Visualization and Coordination One of BIM’s most powerful capabilities is its ability to create rich, detailed 3D models that represent the real-world structure before anything is built. These models don’t just look good—they help designers, engineers, and clients better understand the spatial relationships within the project. This leads to faster approvals, better collaboration, and fewer errors during construction. Clash Detection BIM can automatically identify clashes between systems—such as plumbing running through a steel beam or electrical conduits cutting across HVAC ducts. This automated clash detection prevents costly on-site fixes and change orders. It saves time, money, and prevents disputes among contractors by resolving conflicts virtually before ground is broken. Accurate Quantity Takeoffs and Cost Estimation BIM tools generate material quantities directly from the model, reducing manual calculation errors and time. This means estimators can produce faster and more reliable budgets. Plus, any design change updates quantities and costs in real-time, enabling a more dynamic and responsive cost management process. 4D Scheduling and Time Management By integrating time as a fourth dimension, BIM allows construction schedules to be tied directly to model elements. You can simulate how the project will unfold week by week, identify bottlenecks, and adjust resources before delays occur. This time-linked visualization helps keep the project on track from day one. Facility and Asset Management Even after the building is complete, BIM continues to add value. It stores important data like manufacturer details, maintenance schedules, and system performance logs. Facility managers use this information to plan upkeep, manage spaces, and extend the building’s lifespan—all without digging through paperwork. What is AI? Let’s pause for a second. Before we dive deeper, you need to know exactly what we mean by “AI.” AI or Artificial Intelligence isn’t some distant, sci-fi fantasy anymore. It’s real, and it’s already part of your everyday life. From voice assistants like Alexa and Siri to recommendation systems on Netflix or Spotify, AI is what allows machines to “think,” learn from data, and make decisions or predictions. In the context of construction and BIM, AI refers to intelligent software systems that can process huge amounts of data, recognize patterns, and provide insights faster and often more accurately than a human ever could. Here’s the game-changer: AI doesn’t just follow rules. It learns from patterns. This means it can improve over time, adapt to new types of data, and offer smarter recommendations the more you use it. When you combine that power with BIM’s data-rich environment, you open the door to a whole new level of project planning, risk management, and automation. Advantages of Integration of AI in BIM Wondering why everyone’s talking about AI in BIM? You’re not alone and you’re about to see why this combination is a game changer in the construction world. Let’s dive into the real benefits you can expect: Increased Efficiency Imagine cutting project time without cutting corners. That’s the kind of efficiency AI brings to BIM. AI algorithms can automatically optimize plans, detect inefficiencies, and recommend smarter workflows helping teams complete projects faster. From streamlined scheduling to automated material planning, this means lower labor hours and significant cost savings across the board. Enhanced Accuracy Ever wish you could eliminate those minor errors that later snowball into massive delays? AI-driven BIM tools analyze huge volumes of data from previous projects and real-time inputs to generate highly accurate models and simulations. This reduces human error, improves data consistency, and ensures that the design is constructible and compliant from the start. Better Risk Management What if you could identify potential risks before the first brick is laid? AI enables predictive analytics in BIM, helping teams forecast construction issues—like safety concerns, weather-related delays, or material shortages. By catching problems early, you can take proactive action and avoid costly setbacks, keeping your project timeline intact. Improved Collaboration Collaboration is already a key strength of BIM—but AI takes it to the next level. AI facilitates real-time data analysis and instant feedback across all stakeholders. It bridges communication gaps by providing clear insights, project forecasts, and automated status updates—keeping everyone aligned from design to handover. Enhanced Sustainability Want to build greener without compromising on performance or budget? AI in BIM makes it possible by optimizing energy use, selecting eco-friendly materials, and suggesting efficient layouts. It can simulate energy consumption and carbon footprint before construction even starts—helping you meet sustainability goals and environmental regulations effortlessly. While AI in BIM brings a host of advantages, it’s not all smooth sailing. Let’s take a realistic look at the limitations. Limitations of AI in BIM High Initial Costs AI-powered BIM tools often come with hefty upfront costs. You’ll need to invest in … Read more